How to simplify 5S and 6S warehouse audits with mobile tools. Discover the benefits of digital checklists over paper methods and how apps like Flux streamline the process.

Palletization is the process of stacking and arranging items on pallets for storage, handling, or shipment. Learn why it’s important for shipping efficiency and safety, and how different methods affect pallet building.

Learn how to measure warehouse picking performance (pick rate, accuracy, cycle time) and improve it with better picking methods and slotting.

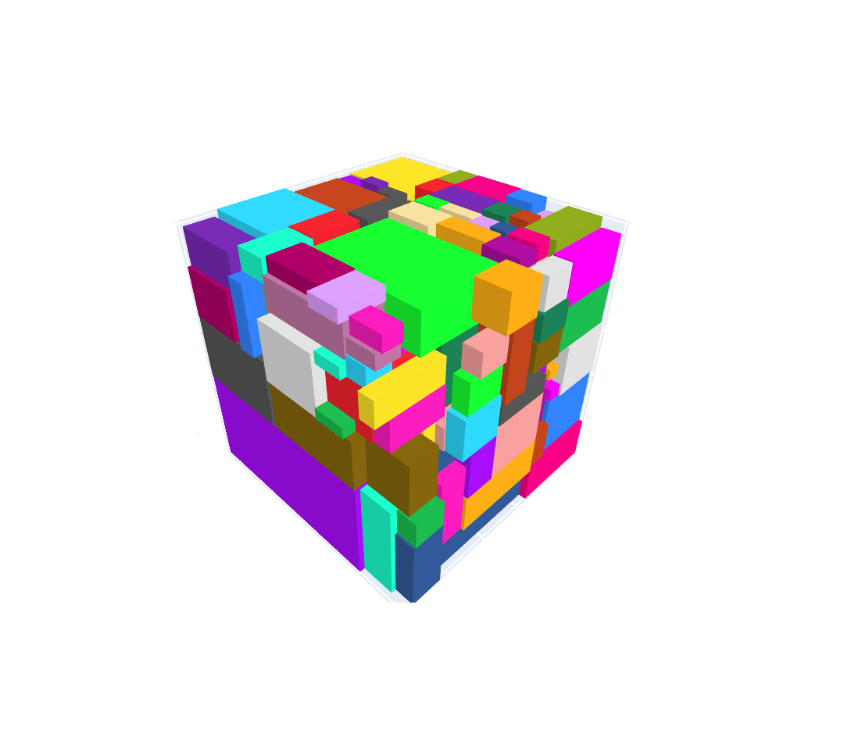

3D bin packing explained for warehouses: how it drives cartonization, pallet stacking, and vehicle loading. Optimize packing process and reduce transport costs with the help of 3D bin packing software.

.png)

Industrial Sites Podcast: Justin Smith and Bart Gadeyne (Optioryx) discuss the quick wins in adding AI optimization to warehouse management systems.

Learn the four main mixed palletization options: from fully manual to fully automated robotic systems. Compare setups, use cases, payback expectations, and how to choose the best approach for your warehouse.

Looking for Lowpad alternatives? Compare AMR robots vs AI picking optimization with a warehouse digital twin. See where robots pay off and where software wins.

Looking for a Power Apps alternative for logistics? Compare Power Apps, Optioryx Flux, Mendix and AppSheet for mobile workflows, scanning, AI, offline use and pricing. See which platform fits logistics operations best.

Turn daily micro-moves into big productivity gains with smart slotting that reduces picker travel, avoids disruptions, and improves throughput.

Episode 4 of Warehouse Wizards with Stefan Rusu of Deloitte, where we explore the orchestration of the Intelligent warehouse with software, automation, and human–machine collaboration.

Eliminate paper forms and manual data entry. Flux by Optioryx is a mobile data-gathering platform that automates dimensioning, OCR, and cargo inspection.

Time-aware scheduling means planning pick-and-pack work by due time first, then by walking efficiency, and updating the plan as new orders arrive.