Discover 6 common warehouse order-picking challenges and solutions. Learn how to overcome inefficiencies, reduce errors, and boost fulfillment performance.

Discover the pros and cons of automation and software optimization in warehousing. Combine both to enhance efficiency and flexibility for your operation.

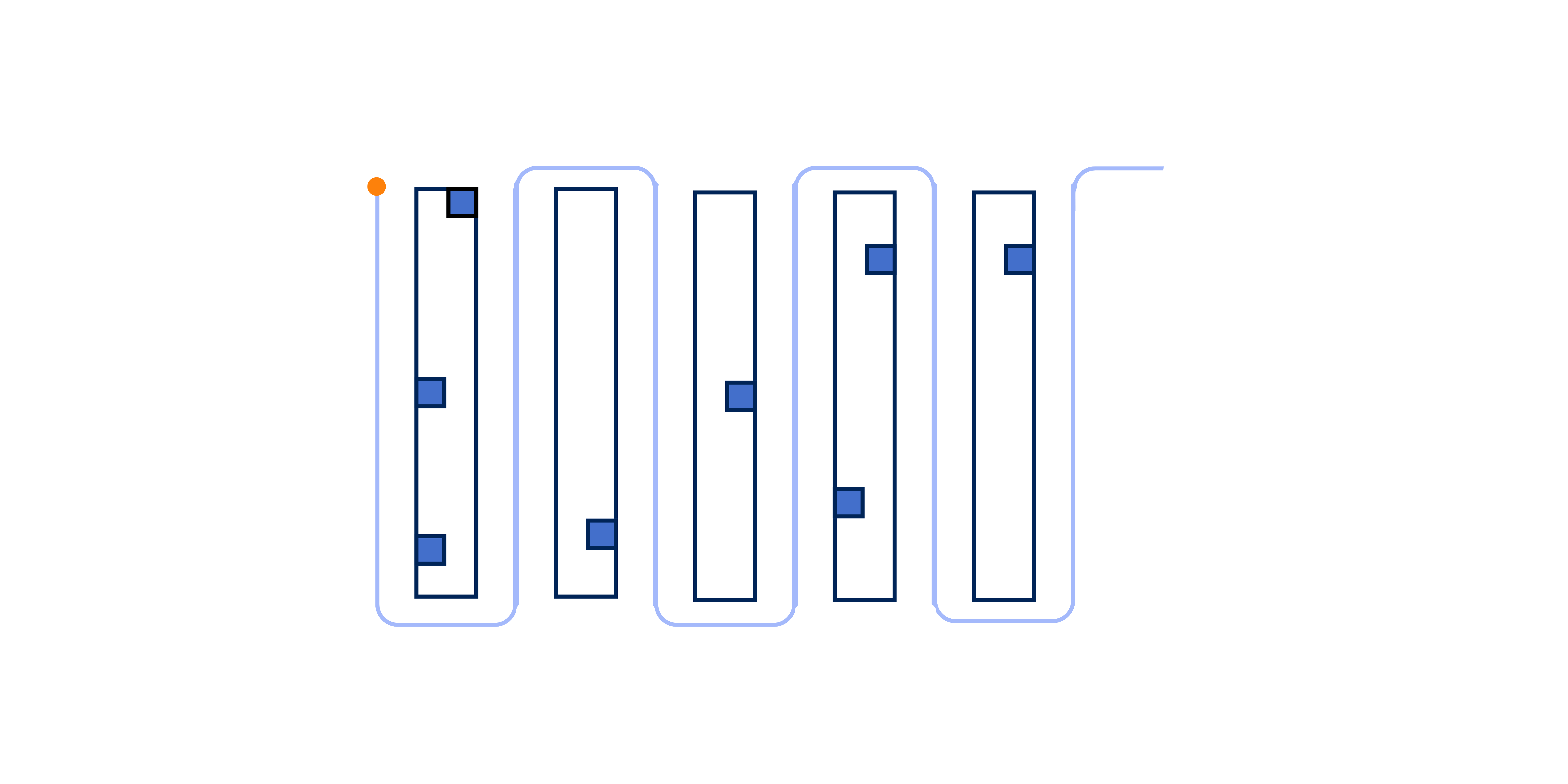

Reduce walking distances by 25-40% and boost productivity of warehouse by 15% with picking optimization modules.

Task interleaving is the practice of combining multiple tasks in a single workflow.

Discover the significance of picking path optimization in your warehouse operations. Learn how optimizing your picking process can benefit your warehouse

Learn how multi-order picking optimizes warehouse efficiency by reducing walking distance and improving labor productivity

Learn about various warehouse picking methods like batch, zone, and cluster picking, and the pros and cons of robotics vs. software in picking operations.

Storage Location Assignment Problem (SLAP) in the context of warehousing involves the allocation of products to specific storage locations within a warehouse.

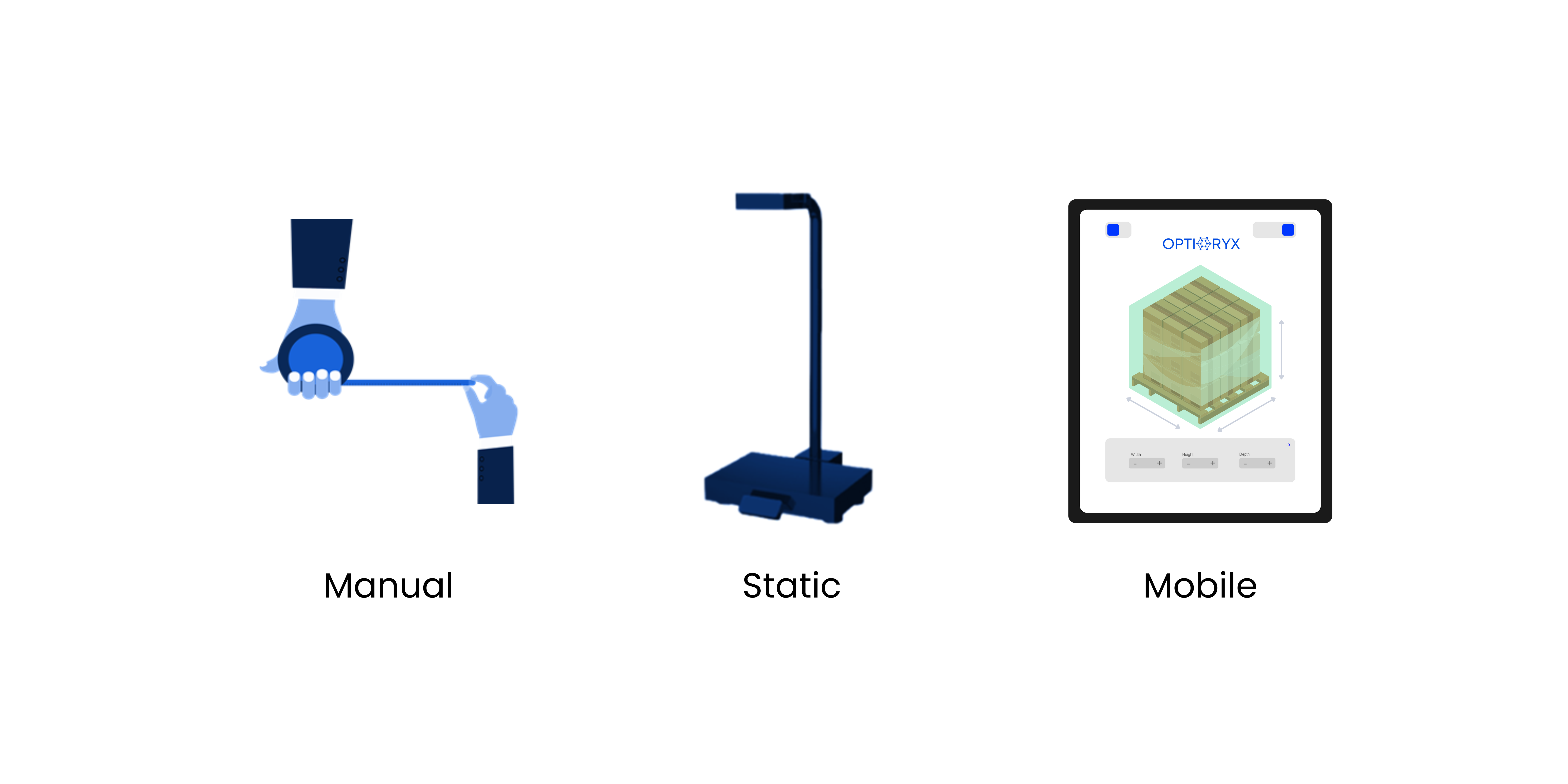

Explore different types of dimensioning methods in warehousing: manual, static, and mobile. Learn about each pros, cons, and limitations.

Warehouse management systems lack optimized solutions for tasks like picking, which can significantly increase warehouse picking productivity

Discover how warehouse digital twins transform warehousing by providing a risk-free playground to explore what-if scenarios

Case picking is the process of selecting individual cases or cartons of products from inventory, typically containing multiple units of SKU.