Picking Optimization

AI-powered tool to reduce the walking distance in warehouses

- Reduce walking distance in warehouses

- Increase warehouse productivity

- Decrease onboarding times of new employees

- Integrate into existing systems

The 2 Modules of Picking Optimization

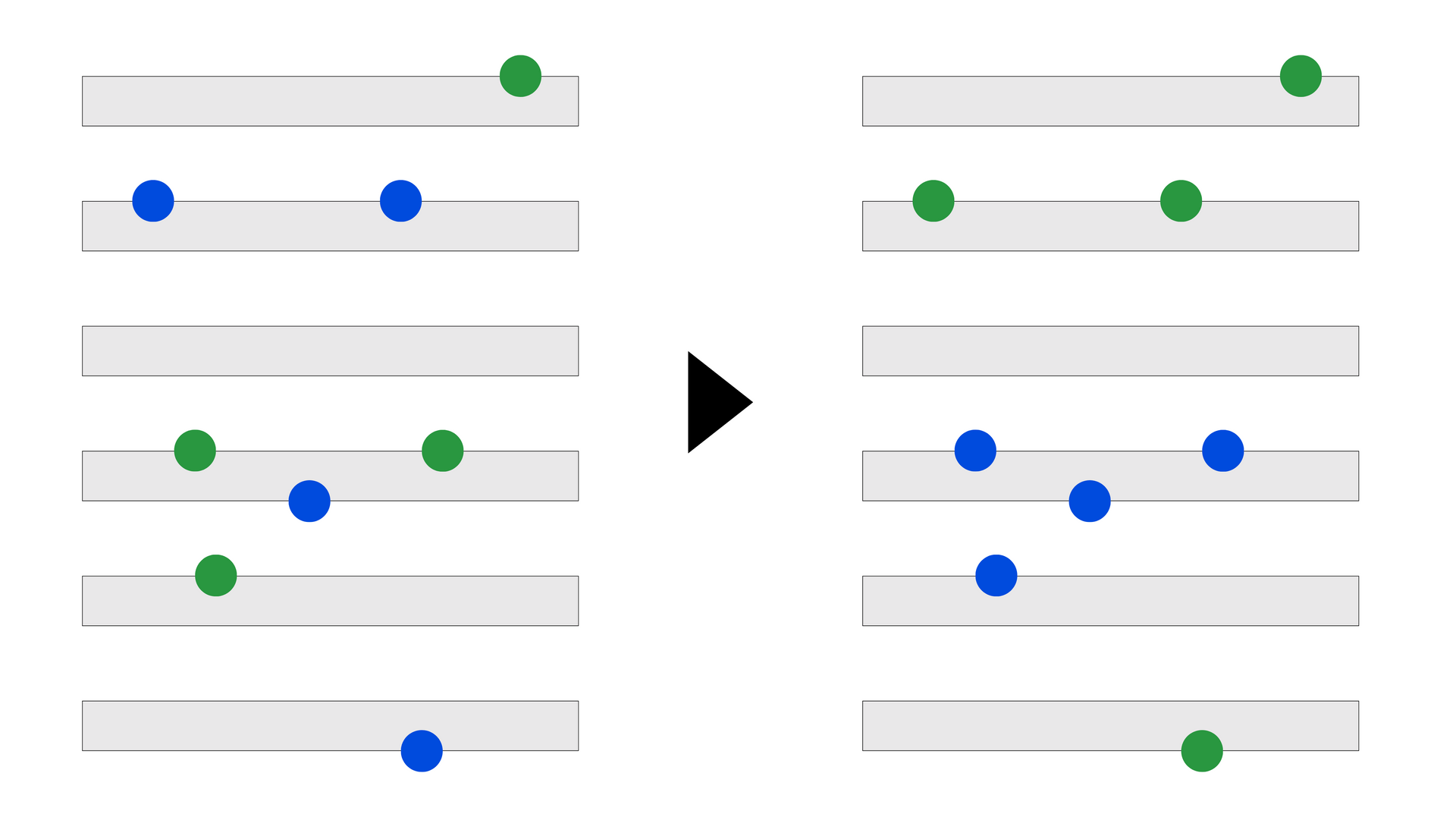

1. Order Clustering

Reduce pick distances by

15 - 30 %

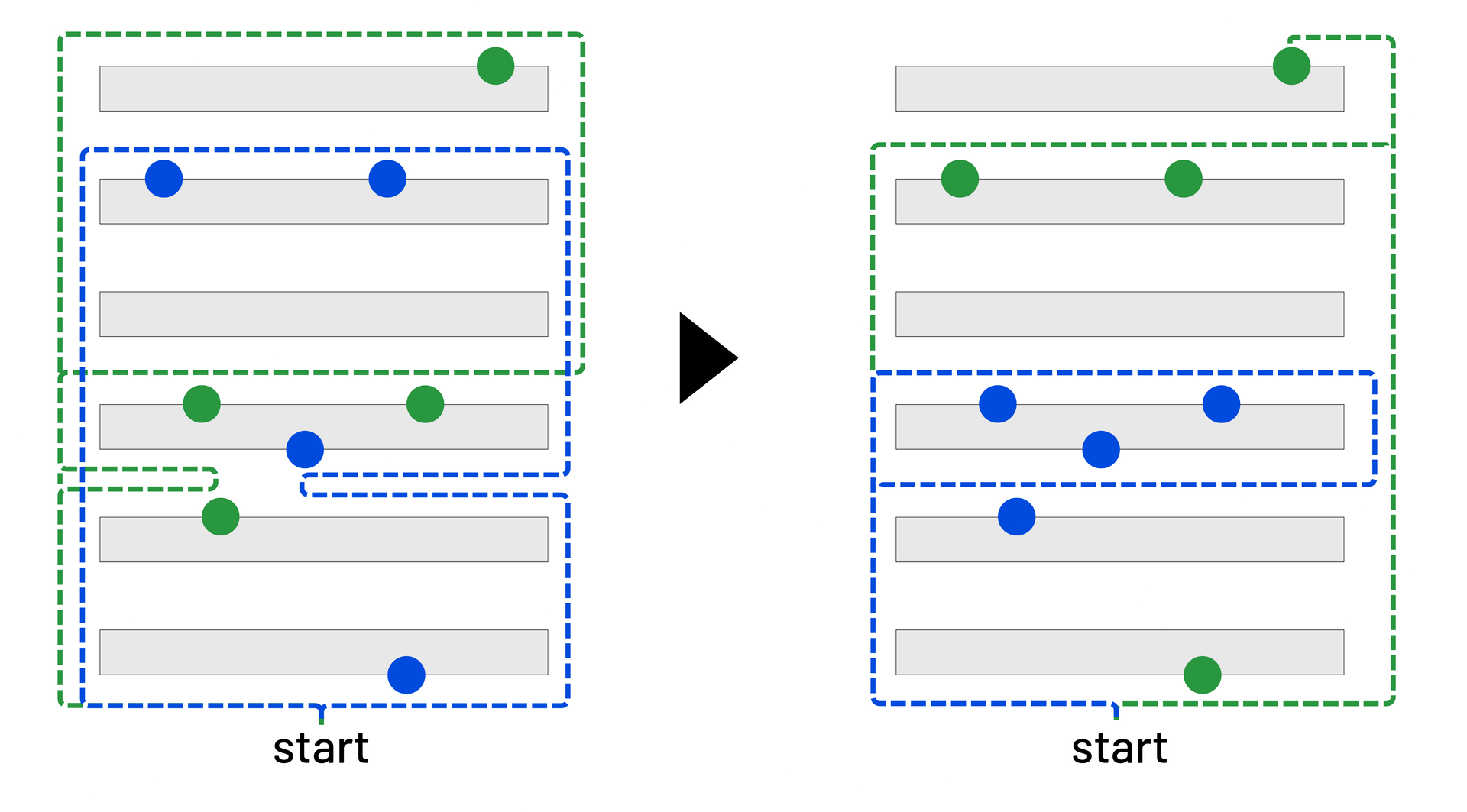

2. Pick Path Optimization

Reduce pick distance by

10 - 20 %

Combine orders into optimized clusters

Generate the shortest pick path within those clusters

Combine Both To Increase Warehouse Productivity

Create routes that minimize the amount of time and energy spent on each pick

25 - 40 %

Decrease in walking

5 - 15 %

Decrease in labor cost

15 % +

Increase warehouse productivity

HOW IT WORKS

Step 1

Upload warehouse layout to make a digital twin of a warehouse

Step 2

Connect WMS or ERP system to

our

API

Step 3

Start using it on operational basis and experience picking productivity increase

Download our One-Pager

Take a look at the features and advantages of applying picking optimization modules

Equip employees with a tool for optimal operations from the start, skipping weeks of onboarding

Frequently Asked Questions

-

What is picking optimization?

Picking optimization is the process of optimizing the path that warehouse workers take in warehouses to minimize the time and effort required to fulfill orders while maximizing accuracy and efficiency.

-

How does picking optimization work?

By combining (1) order clustering which combines orders into a single pick route & (2) pick path optimization which generates the shortest path within that route, warehouses can cut pick distances by 20% to 45%.

-

What are the benefits of picking optimization?

Decrease in walking time, increase in (warehouse) productivity, improve overall efficiency in the picking process, decrease onboarding time of temporary workers.

-

What are the common challenges in picking optimization?

In conventional warehouse operations, pick distances are too long due to basic business rules of order item clustering and common snake-like pick paths.

-

How can picking optimization be implemented into our operations?

Picking Optimization is an add-on in the form of a microservice that works with existing WMS & OMS through an API, adding an extra intelligence layer on top of what you already have.

-

How to get started with Picking Optimization?

Book a demo here and let’s discuss your requirements.

-

Can picking optimization be integrated with packing operations?

Yes. Integrate picking optimization with pick-to-box or pick-to-pallet.

CONTACT US

+32 472 71 51 28

info@optioryx.com

USEFUL LINKS

STAY INFORMED

You need a helping hand with your project?

We will get back to you as soon as possible

Please try again later

CONTACT US

+32 472 71 51 28

info@optioryx.com

USEFUL LINKS

STAY INFORMED

You need a helping hand with your project?

Thank you for subscribing to our newsletter.

Oops, there was an error subscribing to the newsletter.

Please try again later

All Rights Reserved | Optioryx